- Startseite -

- Digital Bavaria -

- Blog #bytevaria - 3D printing, a technology of the future: the future began a long time ago in Bavaria

3D printing, a technology of the future: the future began a long time ago in Bavaria

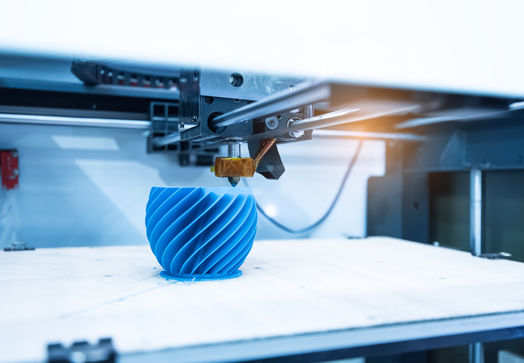

When it comes to cross-industry innovation, 3D printing plays a crucial part. Additive manufacturing can save materials and time and it’s possible to produce more precise components that are stronger. Thanks to networking the process chain using the Industry 4.0 approach, it also manages to manufacture customised elements in small numbers as required.

More and more materials can already be printed today and in ever faster and better quality. While 3D printing once began with plastics, the use of metals has also been successful for a long time. Whether it’s turbine blades, hip joints, soles of shoes or spare parts, additive manufacturing processes are present in all application areas and industries today. As a result, more and more products from 3D printing are being used in mechanical engineering, the aerospace industry and medical technology today.

What is 3D printing?

In contrast to traditional manufacturing process where a material is worn down by turning, milling or boring, 3D printing is a generative process. A workpiece is built up layer by payer by adding materials, which is why it is called additive manufacturing. While at the start it was mainly about the simple manufacturing of prototypes, it has long succeeded in making the jump to be a recognised manufacturing method. The following advantages smoothed the way for the process:

- Production in no time at all

- More complex geometries possible compared to classic manufacturing (milling, welding)

- Less material consumption

- Considerably lighter weights for components

- Functional integration of lines

Promoting technology in Bavaria

The potential of this technology was recognised in Bavaria a long time ago. Which is why the state is placing great importance on promoting research and development projects in the field of “Additive Manufacturing / 3D Printing” as part of the Bayern Digital II master plan and the Bavarian ”New Materials” research programme. Research is mainly to be conducted into collaborations between companies, involving research institutes as necessary. There are currently research projects, for example, at the Universities of Würzburg, Erlangen-Nuremberg and Bayreuth where there is even a newly created Master’s course in “Biofabrication”. In addition, the first BayernLab was also opened in Traunstein in 2016 where anyone interested can test 3D printers themselves.

Leading providers in Bavaria

Concept Laser

Concept Laser GmbH, founded in Lichtenfels, Upper Franconia in 2000, is one of the leading providers of 3D printing for metal components for mechanical and plant engineering. Since December 2016, Concept Laser has been part of GE Additive, a division of the global industrial company General Electric. At least EUR 100 million is going to be invested and 500 new jobs are going to be created at the company head office in Lichtenfels.

EOS Krailling

With its innovative manufacturing systems, EOS in Krailling is one of the technology and quality leaders for high-end additive manufacturing solutions. Founded in 1989, the company is a pioneer and leader in direct metal laser sintering (DMLS) and a provider of highly productive systems for additive manufacturing using plastics. For example, EOS manufactures plastic components on demand in close cooperation with Daimler for its bus subsidiary EvoBus in Neu-Ulm. This avoids excess production and saves on costs in logistics among other things.

ExOne

Besides selling 3D printers, ExOne GmbH also offers the manufacturing of metal and sand components using 3D printing as a service. The US-American parent company recently completed its plant at the European principle place of business in Gersthofen near Augsburg. The plant extends over an area of roughly 14,000 square metres for production, research and development as well as offices.

Voxeljet

The company also based in the greater area of Augsburg has specialised in 3D printing systems for processing plastics, sand and metals. Voxeljet AG develops and sells its 3D printers for industrial use at its head office in Friedberg, Bavaria and is also active at other locations in America, England, China and India.

Other players in the 3D printing sector

The APWORKS company based in Taufkirchen near Munich is part of the Airbus Group and offers 3D metal printing as a service. The entire value creation chain is covered from the optimised design of components to the selection of suitable materials and prototype building to qualified series production. BMW has been using 3D printing technology in its production for a long time and is even opening its own Campus for Additive Manufacturing in Bavaria in 2019. Sandhelden GmbH based in Gersthofen near Augsburg is a provider of washbasins and other plumbing equipment, which are made out of sand using 3D printing. Additive Manufacturing allows for totally new approaches in terms of design and material procurement.

Application areas and industries

- Fuel systems, moving and stationary blades, heat protection components, drive and turbine parts, rocket elements and high-quality components for the cabin and cockpit equipment, among other things, are made using 3D printing processes in the aerospace industry.

- Car manufacturers and suppliers use additive manufacturers, for example, for engine components, bodywork and structural parts and direct components for interiors. It is also suitable for direct components in pre-series development and small parts production.

- Medical technology is building manufacturer-specific modifications with small batch sizes and customised implants up to batch size 1 on 3D printing. But also with the series production of standard implants.

- A variety of dental products like crowns, caps, model casts and secondary constructions, such as mouth guards are being produced in the dental industry.

- 3D printing is being used for customised pieces of jewellery, one-offs, small series or display models in watch and jewellery making.

- There are various applications in tool and mould making, e.g. measuring devices, injection moulding, stapling devices and clamping fixtures for production, cooling channels, etc.

Besides the leading players in 3D printing in Lichtenfels and Munich, a cluster for additive manufacturing has mainly developed in the greater area of Augsburg. Several hidden champions are active in Swabia and sell their highly specialised products worldwide. The Experience Additive Manufacturing multi-location event also took place in Augsburg for the first time this year. Thanks to the involvement of locally based companies and research, a new trade fair concept was developed where accompanying events are also held, for example, in cooperation with the Fraunhofer Institute.

Read more about this topic:

>> 5 minutes with… Mr Frank Herzog, founder and CEO of Concept Laser

>> Best Perspectives: Concept Laser - Where Bavaria is opening up space for new ventures

How a passion can transform into a successful business

Chicago/Planegg-Martinsried: the US-based Proteintech Group triples the size of its site in Bavaria – with a key focus on research & development, production and logistics

![[Translate to English:]](https://ik.imagekit.io/sgliwi1izsz/media/images/team_2021/mitarbeiter/Hr.Julian.Hechler_klein_V1.jpg?tr=w-1024 1024w, https://ik.imagekit.io/sgliwi1izsz/media/images/team_2021/mitarbeiter/Hr.Julian.Hechler_klein_V1.jpg?tr=w-1280 1280w, https://ik.imagekit.io/sgliwi1izsz/media/images/team_2021/mitarbeiter/Hr.Julian.Hechler_klein_V1.jpg?tr=w-1536 1536w, https://ik.imagekit.io/sgliwi1izsz/media/images/team_2021/mitarbeiter/Hr.Julian.Hechler_klein_V1.jpg?tr=w-1920 1920w)